Choosing the Correct Gage Type for Groove Inspection

Von einem Mystery-Man-Autor

Last updated 01 Juni 2024

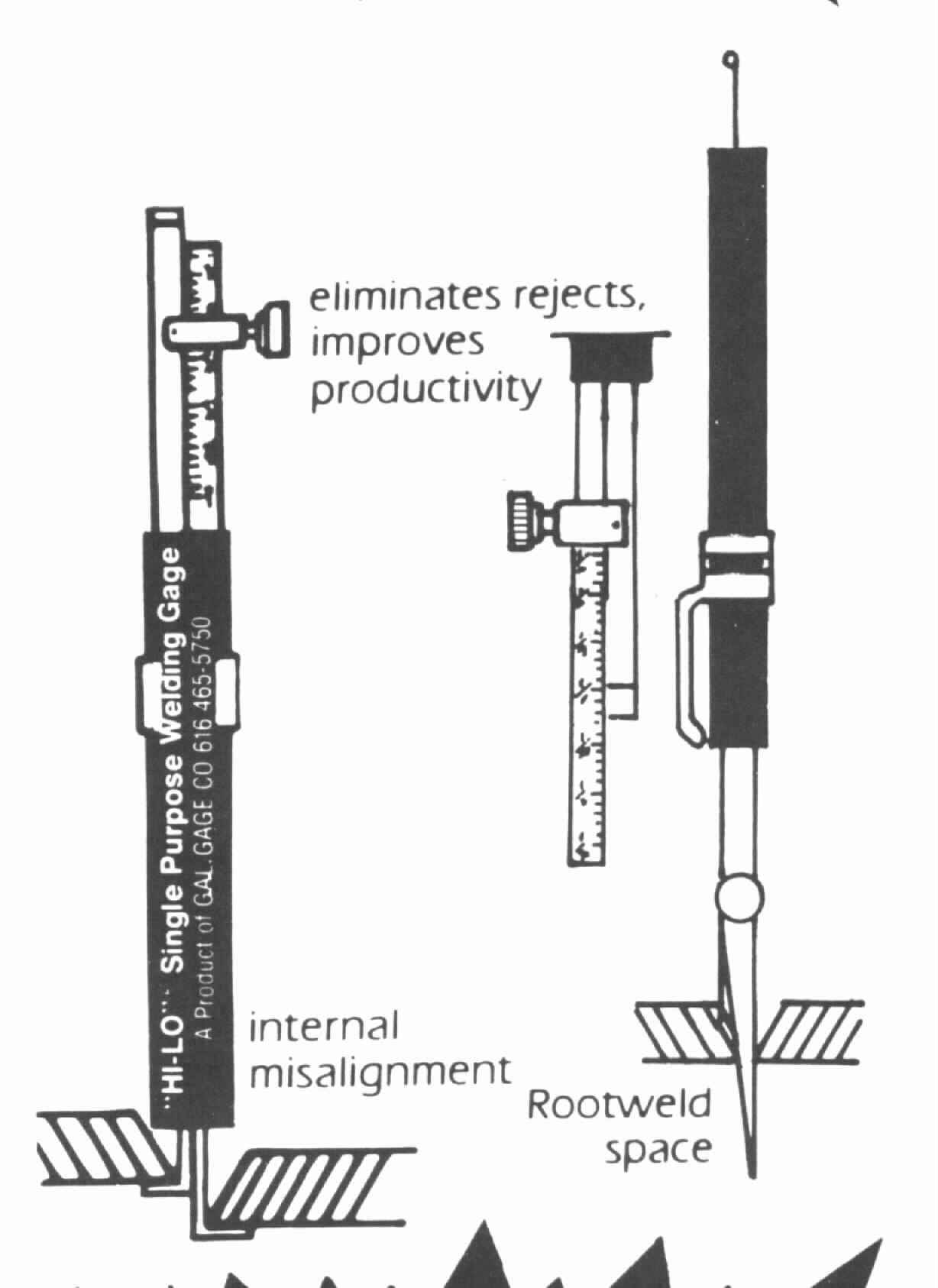

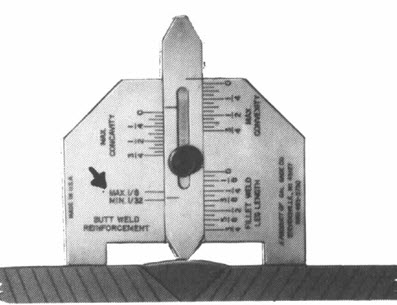

How to read welding inspection gauges, WG series gages

Inspection and Gage Design

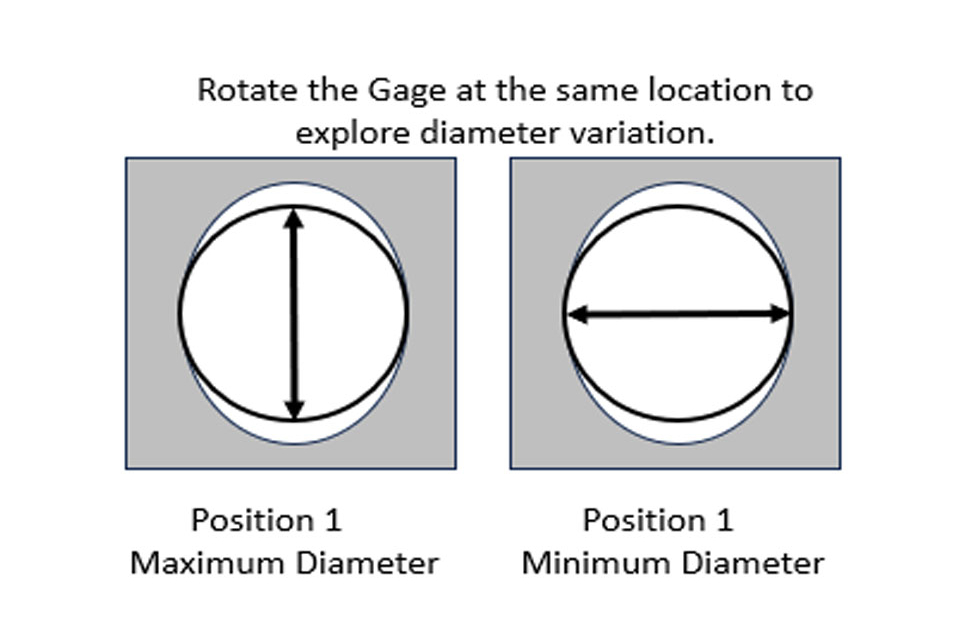

How to Measure Big IDs and ODs

Inspection and Gage Design

102-300 DYER Groove Gage: 2-6/150mm - Call 800-469-0132 or Buy Online

Proper Use of Weld Gages

104-102 DYER Groove Gage: 0.2-0.6 - Call 800-469-0132 or Buy Online

Cylindrical Ring Gages: One Ring to Rule Them All

Inspection and Gage Design

Choosing the Correct Gage Type for Groove Inspection

Mastering the Grooving Process From Design to Inspection - CNC Machining Service, Rapid prototyping

Technical Information: Ball bearing types, selection factors, and bearing load data from SDP/SI

für dich empfohlen

How to Rebuild a Brake Caliper (And Save Money)14 Jul 2023

How to Rebuild a Brake Caliper (And Save Money)14 Jul 2023 KS Tools 150.1965 Universal brake piston re setter tool set, 4 pcs14 Jul 2023

KS Tools 150.1965 Universal brake piston re setter tool set, 4 pcs14 Jul 2023 Eastwood Brake Caliper Piston Retractor Tool14 Jul 2023

Eastwood Brake Caliper Piston Retractor Tool14 Jul 2023 Clean Your Brake Pistons!14 Jul 2023

Clean Your Brake Pistons!14 Jul 2023 22pcs Universal Car Disc Brake Caliper Wind Back Brake Piston14 Jul 2023

22pcs Universal Car Disc Brake Caliper Wind Back Brake Piston14 Jul 2023 Brake Wind Back Tools14 Jul 2023

Brake Wind Back Tools14 Jul 2023 US PRO Tools Ratchet Brake Caliper Piston Spreader, Pad Compressor, Pu14 Jul 2023

US PRO Tools Ratchet Brake Caliper Piston Spreader, Pad Compressor, Pu14 Jul 2023 Under Car Series - TOPTUL The Mark of Professional Tools14 Jul 2023

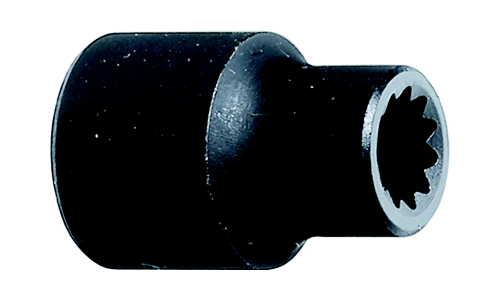

Under Car Series - TOPTUL The Mark of Professional Tools14 Jul 2023 Truck 11 Tooth Disc Brake Caliper Socket14 Jul 2023

Truck 11 Tooth Disc Brake Caliper Socket14 Jul 2023 Goodyear Brake Caliper Piston Rewind Wind Back Tool Kit 2214 Jul 2023

Goodyear Brake Caliper Piston Rewind Wind Back Tool Kit 2214 Jul 2023

Sie können auch mögen

Realky Unterbauleuchte Küche LED, Dimmbar Schrankbeleuchtung Kabellos, LED Lichtleiste mit Aufladbar, USB Batteriebetriebenes Küchenlicht für Spiegel, Schreibtische, Küchen, Schränke und Wand : : Beleuchtung14 Jul 2023

Realky Unterbauleuchte Küche LED, Dimmbar Schrankbeleuchtung Kabellos, LED Lichtleiste mit Aufladbar, USB Batteriebetriebenes Küchenlicht für Spiegel, Schreibtische, Küchen, Schränke und Wand : : Beleuchtung14 Jul 2023 BMOT Starthilfekabel Starterkabel KFZ 6m – BMOT Tool14 Jul 2023

BMOT Starthilfekabel Starterkabel KFZ 6m – BMOT Tool14 Jul 2023 Hebegurt mit verstärkten Endschlaufen14 Jul 2023

Hebegurt mit verstärkten Endschlaufen14 Jul 2023 Wahoo Elemnt Bolt (V2) im Test — 169k - Ein Radblog14 Jul 2023

Wahoo Elemnt Bolt (V2) im Test — 169k - Ein Radblog14 Jul 2023 Terraforming Mars: Big Box (2021) - Jeux de Plateau14 Jul 2023

Terraforming Mars: Big Box (2021) - Jeux de Plateau14 Jul 2023 Flachsteckhülsen gelb 6,4 mm 4 - 6 mm² VPE 100 Stück14 Jul 2023

Flachsteckhülsen gelb 6,4 mm 4 - 6 mm² VPE 100 Stück14 Jul 2023 Camera cover – Smoothbev14 Jul 2023

Camera cover – Smoothbev14 Jul 2023) Buy AutoFurnish ARC Green Car Cover Compatible For Nissan Micra Active, Water Resistant, Stripe Design, Triple-Stitched, Dust and Heat Protection, 190T Taffeta, Elastic Bottom, Heavy Buckle14 Jul 2023

Buy AutoFurnish ARC Green Car Cover Compatible For Nissan Micra Active, Water Resistant, Stripe Design, Triple-Stitched, Dust and Heat Protection, 190T Taffeta, Elastic Bottom, Heavy Buckle14 Jul 2023 Memphis Magic Dust 240g14 Jul 2023

Memphis Magic Dust 240g14 Jul 2023 m.media-.com/images/I/712N8JhjNJL._AC_UF89414 Jul 2023

m.media-.com/images/I/712N8JhjNJL._AC_UF89414 Jul 2023